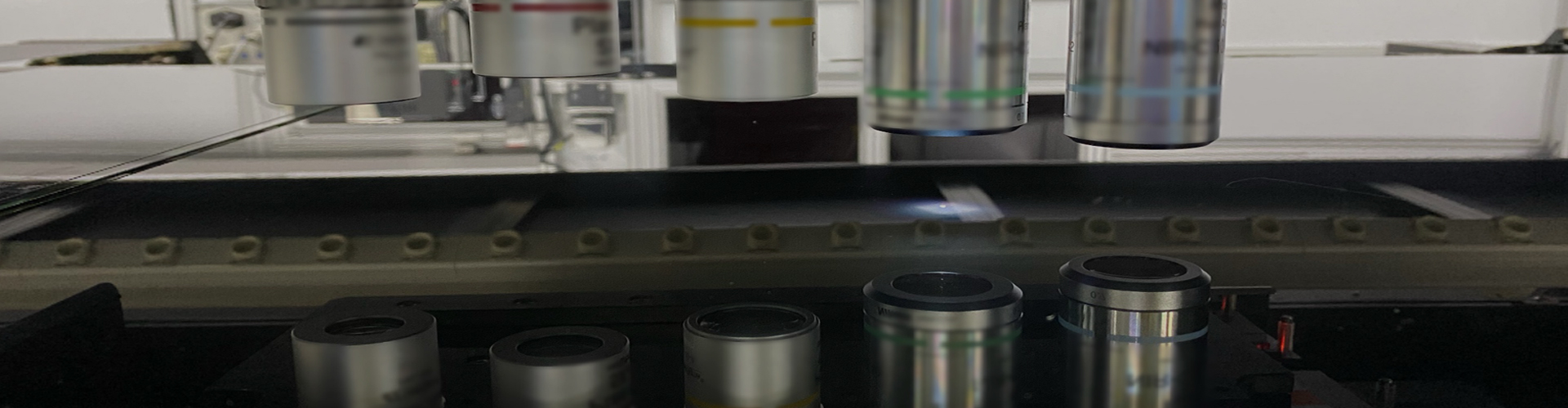

Because the laser processing technology has the characteristics of high precision, small heat affected area, and good controllability, lasers are widely used in the automobile and motorcycle accessories hardware industry.

Laser cutting technology can perform two- and three-dimensional high-precision cutting of automotive special-shaped central control displays, automotive doors, door frames, trunks, roof covers, brake pads, and parts according to requirements. Help auto manufacturers to effectively increase production capacity while reducing production costs.

Laser welding has the characteristics of small heat-affected zone, narrow welding seam, fast welding speed and small workpiece deformation. It is not only suitable for welding of stainless steel and carbon steel, but also for welding of junctions, aluminum and other metals, and can weld different forms of welding. Sew. Laser welding technology is mainly used for welding automobile bodies and splicing blank plates, welding gears, baffles, instrument panels and other parts; effectively improving processing efficiency.

At the same time, laser marking technology, laser cladding technology, and laser surface hardening technology also provide different solutions for the automobile and motorcycle accessories hardware industry.

Home

Home Phone

Phone Contact

Contact